HIGH-PERFORMANCE SOLUTIONS FOR MOTORS AND CONTROLLERS

In order to make electric powertrains achieve their highest performance, the battery is a key component, but it is also not enough alone. A full range of power electronic systems is required to properly manage the high voltage current channels running all the way from battery cells to the e-motor. It is also a must to have those e-motors enabled to run at full power, at high temperature, and for long distances without any decrease in their performance and reliability.

Sika solutions for assembly of ECU’s – the brains, the host of electronic controllers throughout the vehicle – the nervous system, and specialized encapsulation of electric drive motor components - the legs for propulsion, ensures reliable performance and adds value to assembly processes.

CHARGE YOUR AMBITION

Dielectric Potting – Computers & Controllers

Our SikaBiresin® RE series products are equally at home in dielectric potting applications and encapsulation applications. For OBC and DC inverter applications the RE performance properties meet new standards for high voltage, offer reliable and durable performance at high and lower temperatures, enable thermal transfer, have high chemical/environmental resistance, and perform with high, robust dielectric ranges.

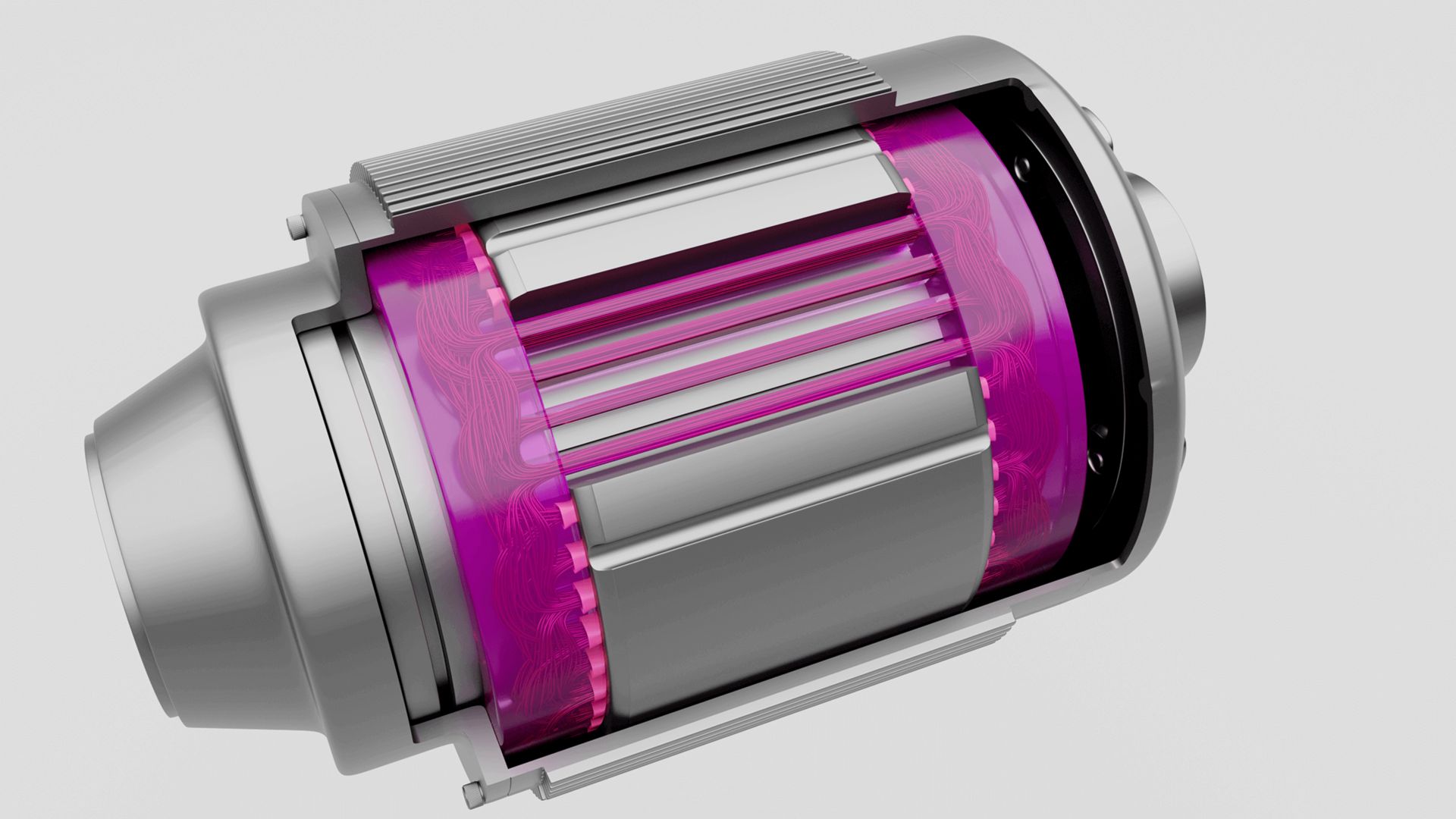

E-Motors

SikaBiresin® TC and RE series products for encapsulation offer excellent advantages to performance both in operation and in assembly processes. Just as heat is the enemy of battery performance so is motor performance at high temperatures. SikaBiresin® products for e-motors offer high thermal conductivity – (1.2 W/m.k) with excellent dielectric properties (24 kV/mm) and impregnation performance (low-viscosity). Products have durable adhesion to various metals and substrates, are durable even at high-temperature exposure, resist cracking and are thermal class H products with a working temperature of 180°C. Another plus, some newly developed products are room temperature cured cutting heated curing time of 4 hours in half during the manufacturing process.