Cells, Modules, Packs & Safety

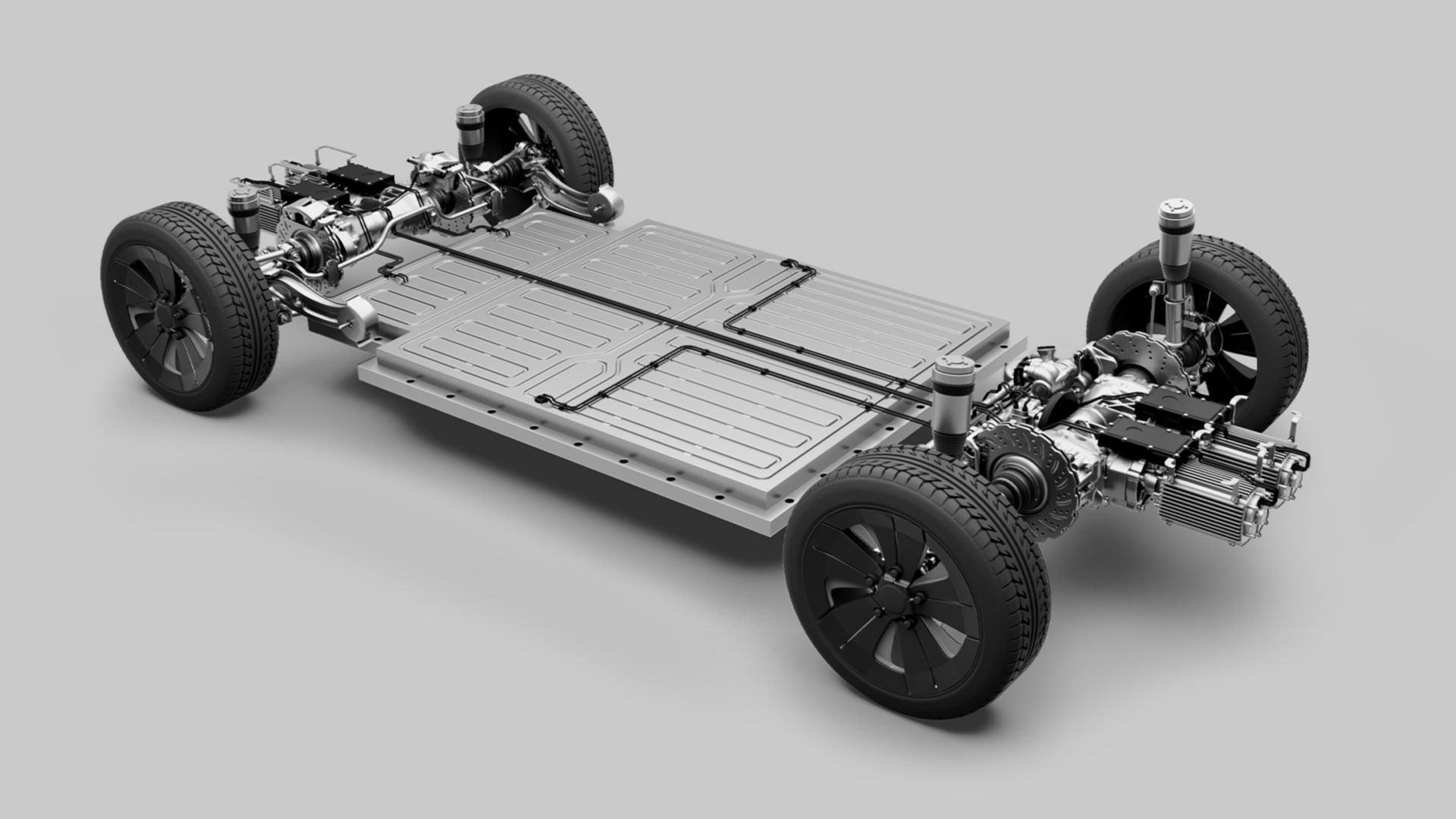

The electrification of our industry brings about challenges but also benefits sustainability in a way that further allows Sika to embrace the future of E-Mobility. Our reach includes many technologies for bonding and sealing, founded in our 100+ year heritage, drawing on experience and innovation along with our vast product range serving many markets around the world. The challenges presented in this new era of electric powertrain are solved readily with Sika expertise, focusing on a specific problem with a specific solution. Challenging applications, materials and functionality requirements allow Sika, with our solutions, to add value in vehicle performance, safety and assembly processes giving customers a full package of service, from concept to production. Sika solutions enable simple, faster and safer construction of thermally managed battery packs and full electric chassis or “skateboards”.

CHARGE YOUR AMBITION

In the Battery Modules - Cell Array Heat Management & Mechanical Performance Improvements

Sika's high performing bonding solutions offer high thermal-conductivity and electrical isolation for packing the cell arrays into battery modules. Our extensive range is based on Epoxy, Acrylic, Polyurethane and STP (Silane-Terminated Polymer) technology and are used to enhance the heat transfer between battery cells and cooling plates or ribbons whilst improving structural stiffness making modules lighter and stronger. They offer thermal conductivity performance up to 2.0 W/m.K as well as high strength and excellent adhesion to many common materials found in modules with limited to no surface pretreatment. All thermally conductive adhesives perform to the UL94-V0 standard and are designed for ease of use in both manual and automated equipment.

Battery Pack Housing Construction

For battery pack housing assembly Sika offers the broadest range of products in the industry, drawing on vast experience in basic and advanced sealing and bonding applications. We continue to be innovative in our approach to new and increasingly more challenging applications such as bonding raw metallic substrates, plastics and composites whilst maintaining good resistance to heat and chemicals like Ethylene Glycol. We must consider the effect of delta-alpha or thermal coefficients of different materials when joining them and we can still achieve this with cold assembly processes. We have a broad range to select from within our global portfolio of products including; one and two-component or boosted polyurethanes, silicones, STP's (Silane-Terminated Polymer), MMA (Methyl methacrylate), epoxies, hybrids, hotmelts and PSA's (Pressure sensitive adhesives). Matched or mixed material bonding is achieved with a number of options offering flexibility in the manufacturing process and overall technical and safety requirements of the construction.

Answering the Call for Fire Safety

Sika has a wide range of products to prevent the spread of fire in a battery pack. Sikaflex® and Sikasil® are flexible polyurethane, STP (Silane-Terminated Polymer) or silicone adhesives and sealants designed to provide a barrier to fire and the associated dangers of a thermal runaway. Sika's fire rated products are fully tested to conform to the most demanding standards in today's electric vehicles to give manufacturers peace of mind and consumers, confidence in this new technology.

Bringing it all Together

Finally closing the battery lid to protect the electronic components inside with a watertight seal is a core competency of Sika. Our range of Sikaflex® materials have been developed over decades in the automotive market and allow for simple assembly and disassembly. Incorporating Sika's booster technology, these sealants can provide a fast and efficient manufacturing process and reduce the wait time for end-of-line pressure testing. Alongside our market leading Sikaflex® we also have a range of CIPG (Cure In Place Gaskets) and SikaLastomer® butyl sealants for fast processing and easy servicing throughout the lifetime of the product. From the cell to the overall battery pack, Sika solutions answer the demands of new innovative designs and assembly challenges.

SikaBiresin® TC range of solutions are thermally conductive gap fillers used to serve as a functional interface between heat generating electronic components and their cooling management systems. The materials which are based on Sika's STP (Silane-Terminated Polymer) or silicone technology are designed to facilitate the transfer of heat to cool or heat components. Performance levels are available with high heat transfer up to 3W/m.K and excellent chemical resistance against substances such as Ethylene Glycol. Our products are designed to conform to the most stringent fire safety standards including the widely used UL94-V0. Moreover, careful consideration is made for application properties including low abrasive formulas to be used in automated equipment, injectable solutions for flexibility in manufacturing process and low compression forces for ease of assembly.