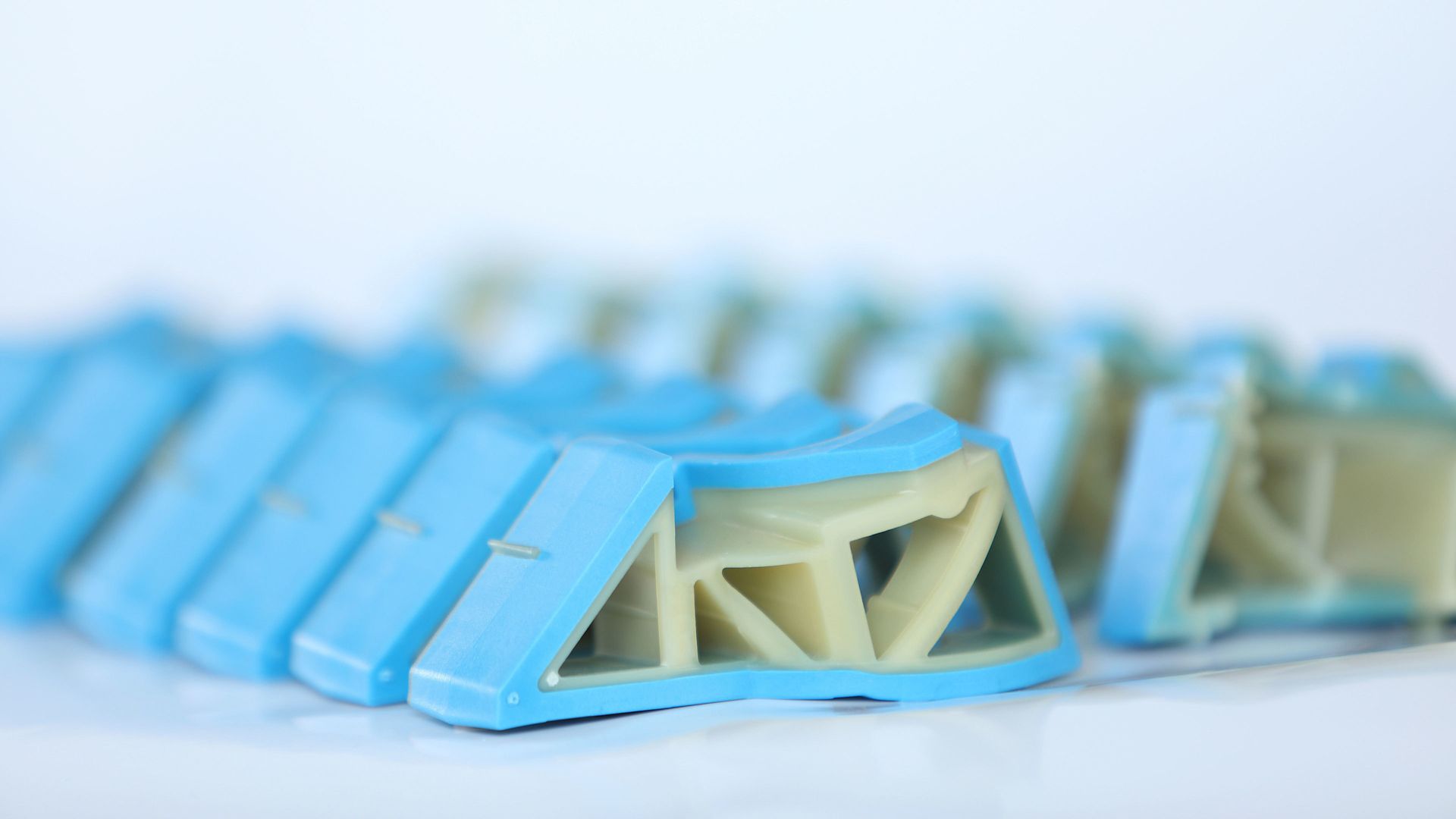

SikaReinforcer® is a heat-reactive and foamable epoxy material that is used in combination with our SikaStructure® carrier to reinforce vehicle body structures. After curing in the E-coat oven, SikaReinforcer® foam creates a strong connection between the SikaStructure® carrier and the car body’s metal sheets.

Get a study suited for you demands now! Book an appointment with our sika expert or get in touch via email.

Deformation Performance in Drop Tower Testing

Comparative crash behaviour of 3 reinforcement solutions in drop tower test on a hat profile: - HSB can withstand the hifhes load and reduce deformation in car body section.

Sika offers tailor made solutions to multiple body shop assembly challenges.

For each type of requirement in crash, local stiffness, NVH and fatigue, Sika’s broad reinforcerproduct range allows for the best design and technical solution; always adapted to the car bodydesign, the planned assembly process and the development timeline. Our engineers propose themost optimized solution for the best results.

Safety Vehicles

Vehicle safety standards have evolved over the years, and as a result, modern cars are safer than they used to be. Today, safety is a mandatory requirement for all car models to comply with regional safety regulations. The need for specific tests, additional weight due to new equipment, and the rise in electro mobility offers new challenges to development engineers.

The solution is to use intelligent SikaReinforcer solutions which make it possible to eliminate costly steel reinforcements in very high performance steels, and which simplify the assembly of local composite reinforcements with equivalent performance versus current assembly and welding processes. Structural foam or structural adhesive will allow a perfect fixation to the surrounding sheet metal.

Benefits:

- Design flexibility even in complex design or thin environments

- Can even reinforce the highest performing steel grades

- Implementable without significant modification of the steel environment design

- Shorter design and development timeline than steel solutions that need many welding operations

- Can be added at any point during the body development process if needed

- Easy assembly process in car body

- Optimal solution for derivative models

Noise

NVH (Noise, Vibration, Hashness) can be a major source of discomfort, and can lead to stress, fatigue. By improving the NVH performance in a vehicle, passengers are more likely to feel relaxed and enjoy their journey. At the same time, local weaknesses can lead to failures of the carbody. A proper treatment is necessary to obtain a long life time of the vehicle.

Replace local steel reinforcement by SikaReinforcer thermoplastic components with structural foam which allows a transfer of load from one side of the section to the other side. It results in a very stiff volume which has a positive impact on the global dynamic NVH performance and can improve the static stiffness at the same time.

Benefits:

- Design flexibility even in complex design environments

- Implementable without significant modification of the steel environment design

- Easier assembly process in the car body, compared to equivalent steel solutions currently available

- Shorter design and development timeline than steel solutions

- Can be added at any point during the body development process

Lightweight Vehicles

Even if electro-mobility mitigated the technical interest of weight saving in the car-body construction, electrification poses additional challenges since the batteries or added electrical components make them heavier than the conventional ICE vehicles. Since EVs are typically 125% heavier than ICE equivalents, there is a need to reduce weight in order to increase the driving range from a single battery charge.

Usually, using alternative materials is an option, but they come at a higher cost. A cost-effective approach is to implement intelligent solutions such as reducing sheet thickness and using local SikaReinforcer composite reinforcements or replacing complex steel reinforcement elements with easy-to-assemble thermoplastic parts.

Benefits:

- Higher cost savings per kg than CFRP or Aluminium

- Allow that Large steel components will be reinforced only locally

- Design flexibility even in complex design environmentsImplementable without significant modification of the heavier steel environment design

- Easier assembly process in car body than equivalent performing steel solution

- Shorter design and development timeline than steel solutions