Innovations in fillers and adhesives are improving thermal conductivity and stiffness properties of car batteries.

The batteries in electric vehicles do not cope well with fluctuations in temperature. Temperatures of below zero decrease range, while those in excess of 70° Celsius shorten battery life. Above 140° Celsius, batteries pose a safety risk. The most important factors that directly impact the performance and safety of electric vehicles are heat control and dissipation. High temperatures such as those generated by battery discharge as a result of high driving speeds or through rapid charging reduce the performance, reliability, and longevity of battery systems. Furthermore, the high temperatures in lithium-ion battery cells are ultimately a fire risk. Sika has developed high-performance technologies for heat control in the complex battery systems in electric vehicles.

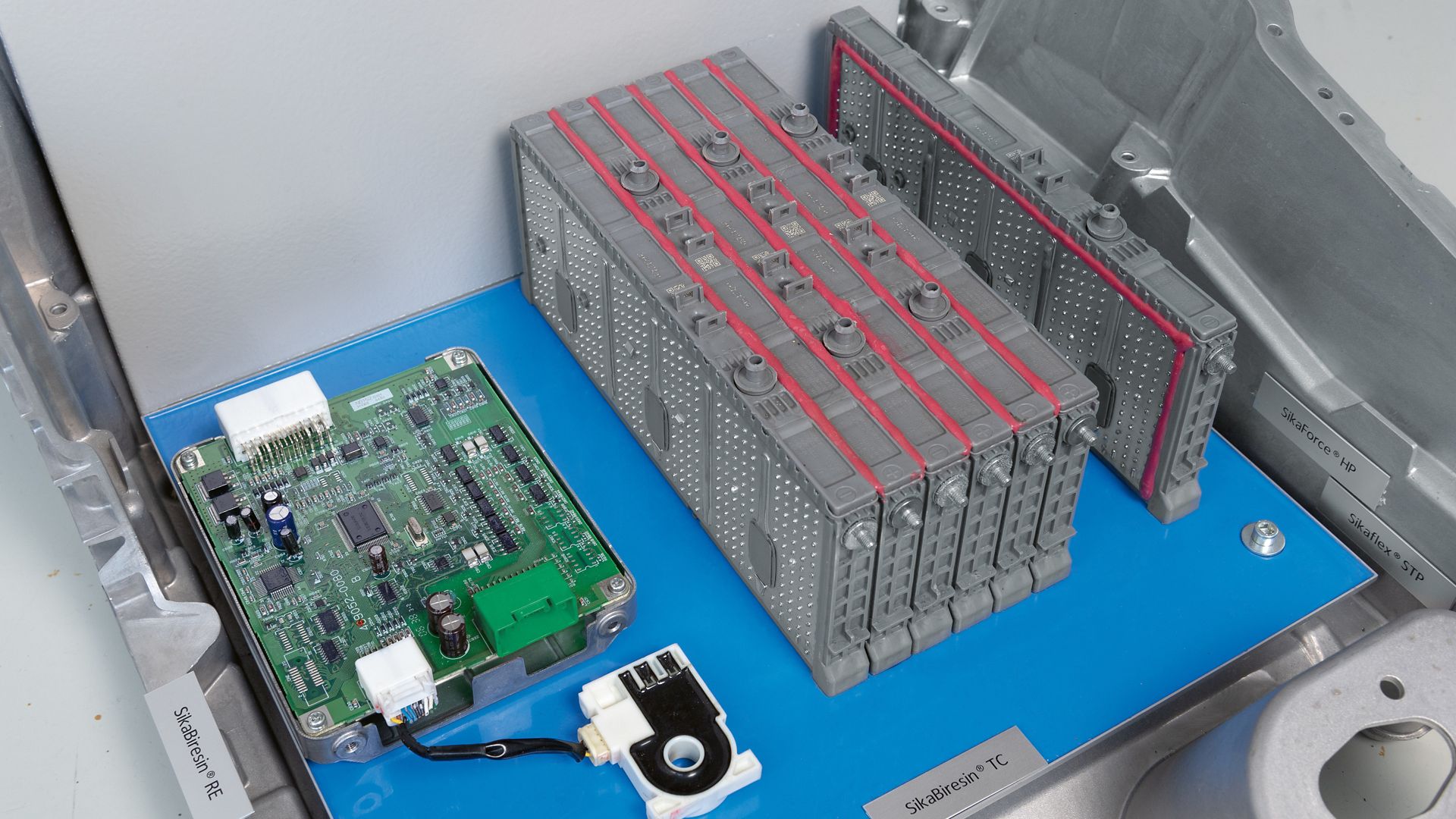

With SikaBiresin® TC and SikaForce® TC, the company has gap fillers and structural adhesives that offer excellent thermal conductivity properties and, at the same time, improve battery pack and battery module stiffness. This allows the modules to be stably affixed in the casing while at the same time the heat is dissipated from the battery modules to the cooling system.